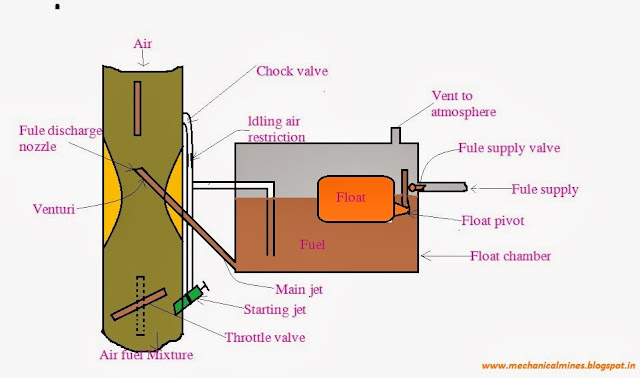

A

modern carburetor for mixing air and fuel in the required proportion for

various operating conditions of SI engine is as shown in fig. The fuel level in

the float chamber is maintained by the float by opening and closeing the fuel

supply line from the main tank. When the fuel level decreases in the float

chamber, the balls resting on the float push the spindle upwards to open the

fuel supply line and more fuel comes into the float chamber.

At

the starting of the engine, fuel is filled up to the maximum level in the float

chamber and compensating wall. All the three jets, that is starting jet, idling

jet and main jet start supplying fuel simultaneously at the starting time

making the air fuel mixture a rich one

( 5:1 ). When the throttle is further

opened to increase the engine sperd, more air enters the inlet manifold and

also the starting and jets stop fuel supply as the fuel level in compensating

well drops quickly. This makes the air-fuel mixture a little lean( 10:1 )

during idling period. The throttle valve is further opened to increase the

power generating capacity during the normal operating conducting condition only

main jet supplies fuel in full capacity as the restricted orifice almost stops

the fuel supply to idling jey. When the engine is stopped, the fuel is filled

up in the float chamber and compensating well to the initial level.

The throttle valve is used to open and close the inlet manifold during

the engine operation to vary the air quantity and also to vary the air-fuel

mixture. The choke valve is used during cold starting condition by closing the

entry of the inlet manifold to reduce the air quantity and thereby reducing the

air-fuel ratio to even below that of 5:1 and making the mixture a vary rich

one.

No comments:

Post a Comment